🏠 Back to the Table of Contents

Research results

Materials

Microstructure model and mechanical behavior of cemented tungsten carbides

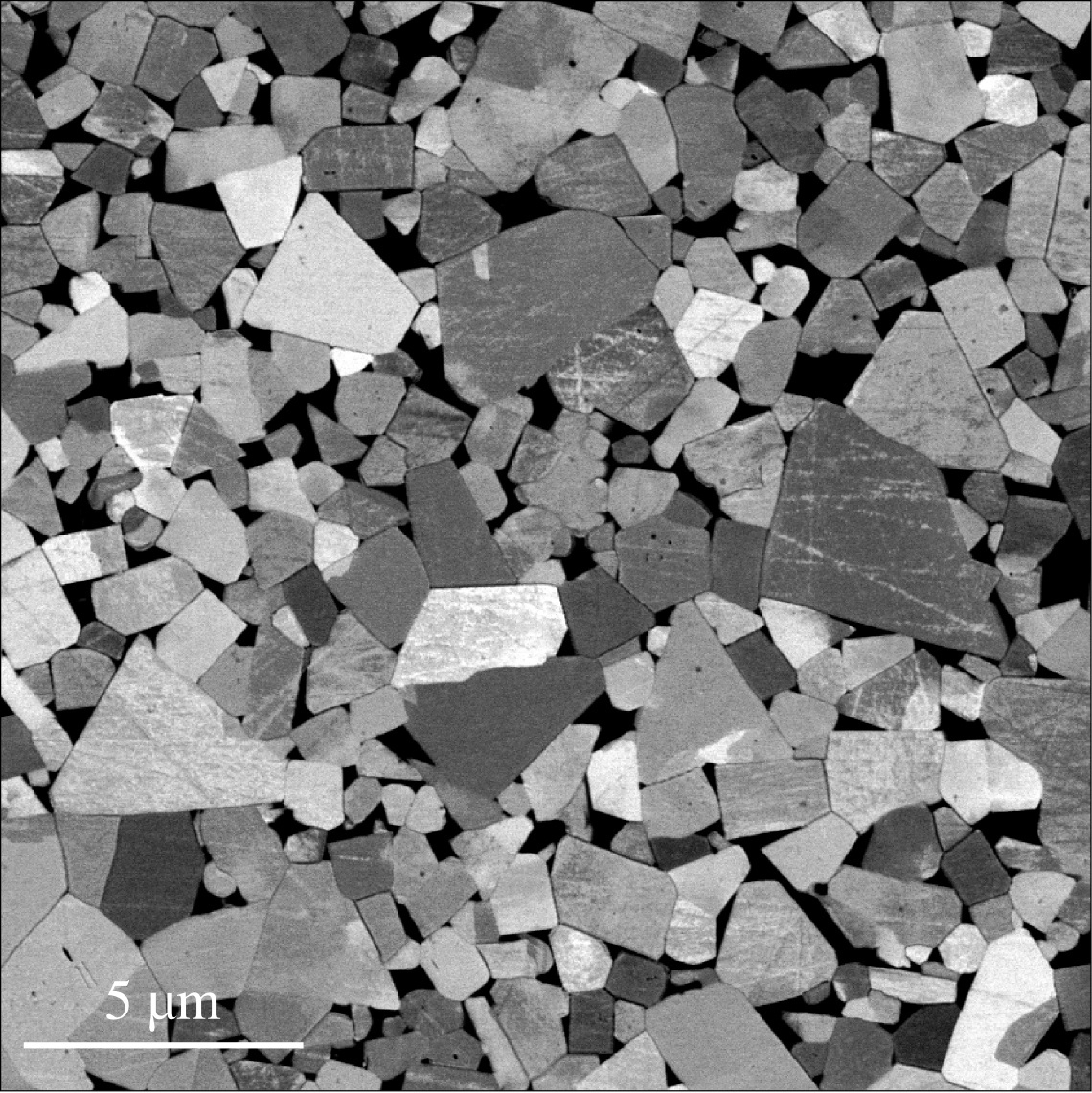

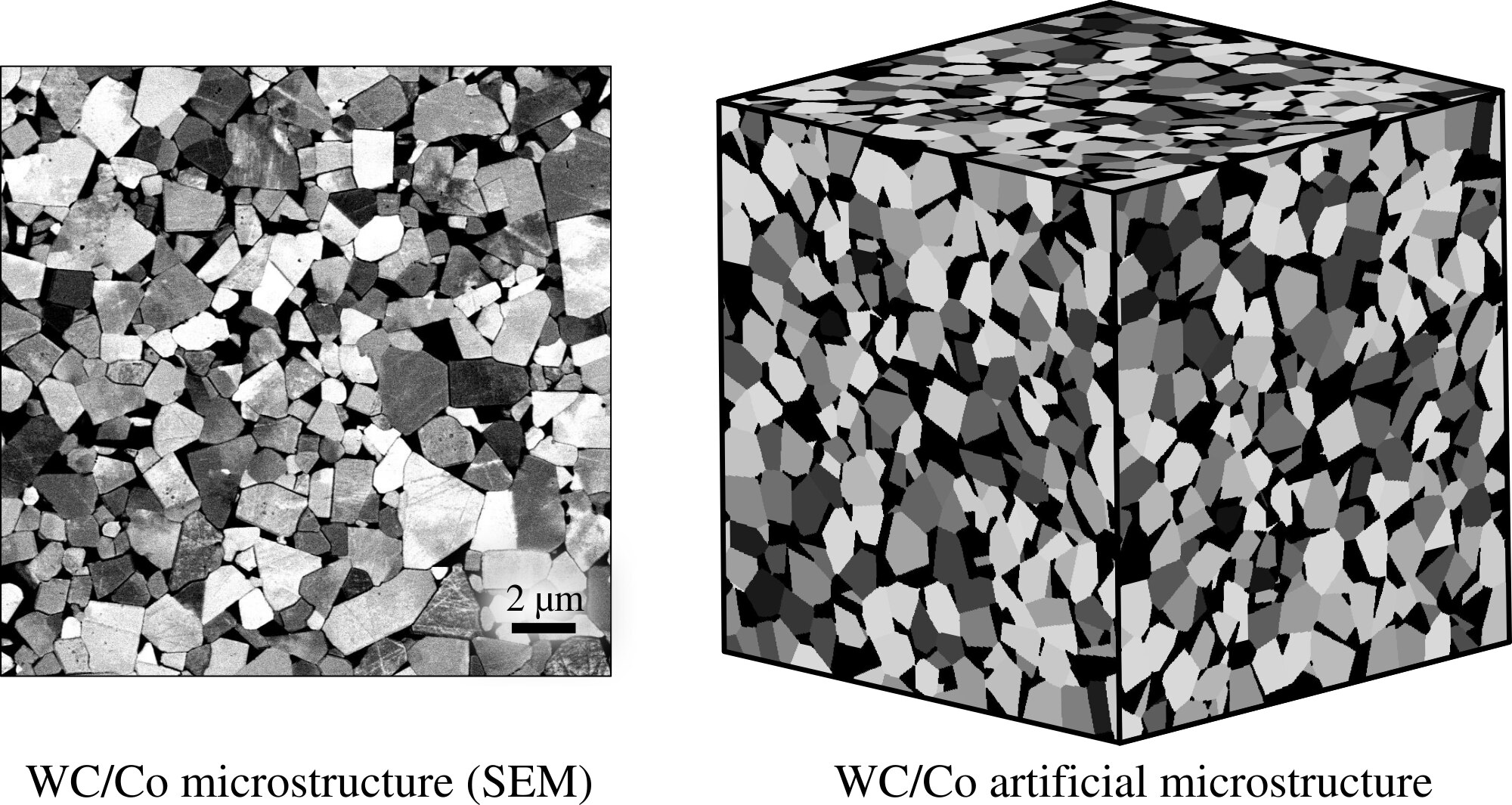

It is not difficult to reconstruct plane microstructure of cemented tungsten carbide using high quality SEM images, even though we did not succeed to fully automatize such a procedure.

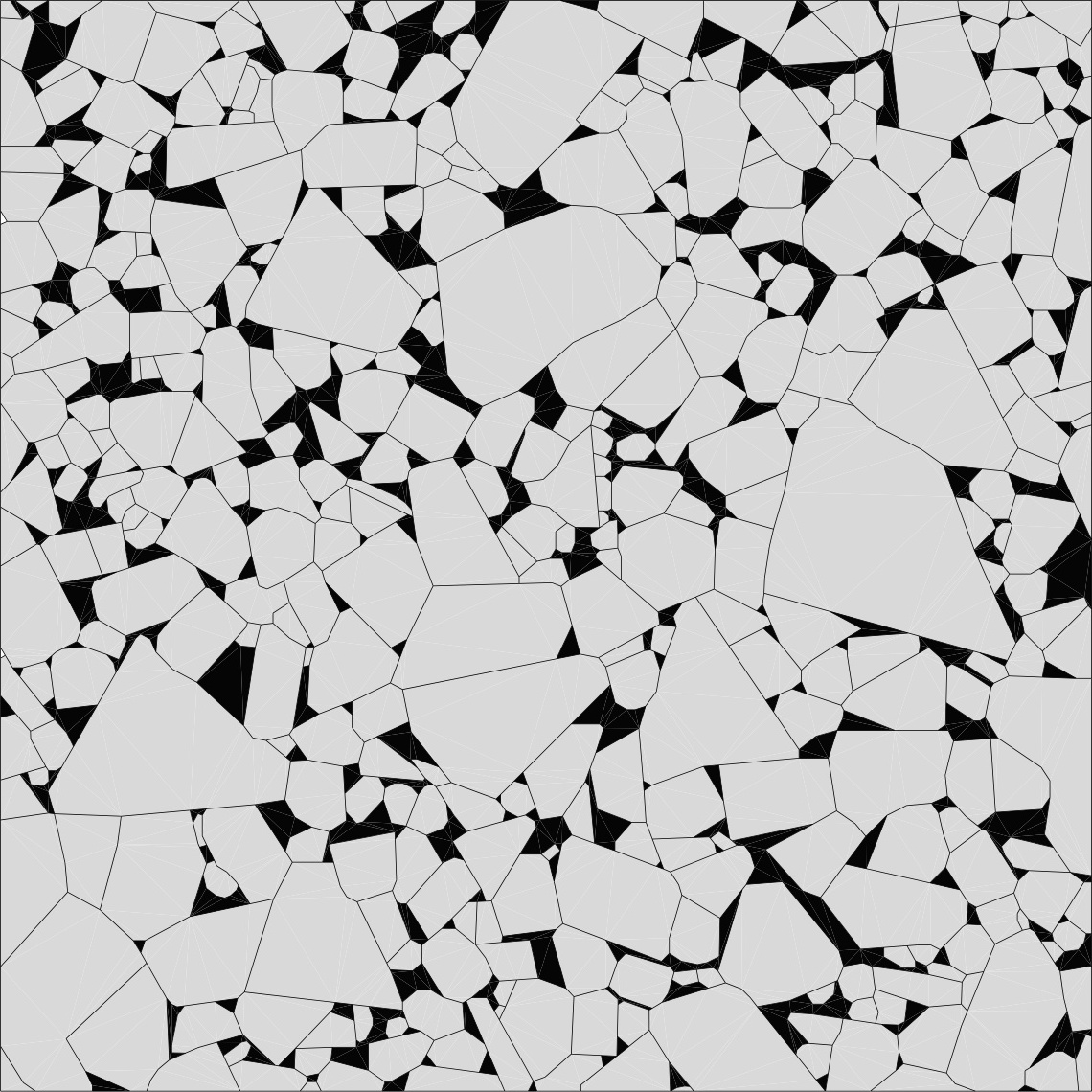

SEM image of WC/Co outlined microstructure finite element mesh [79]

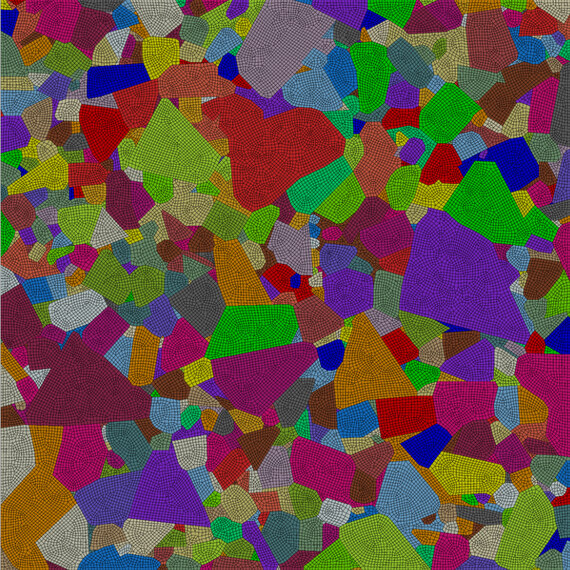

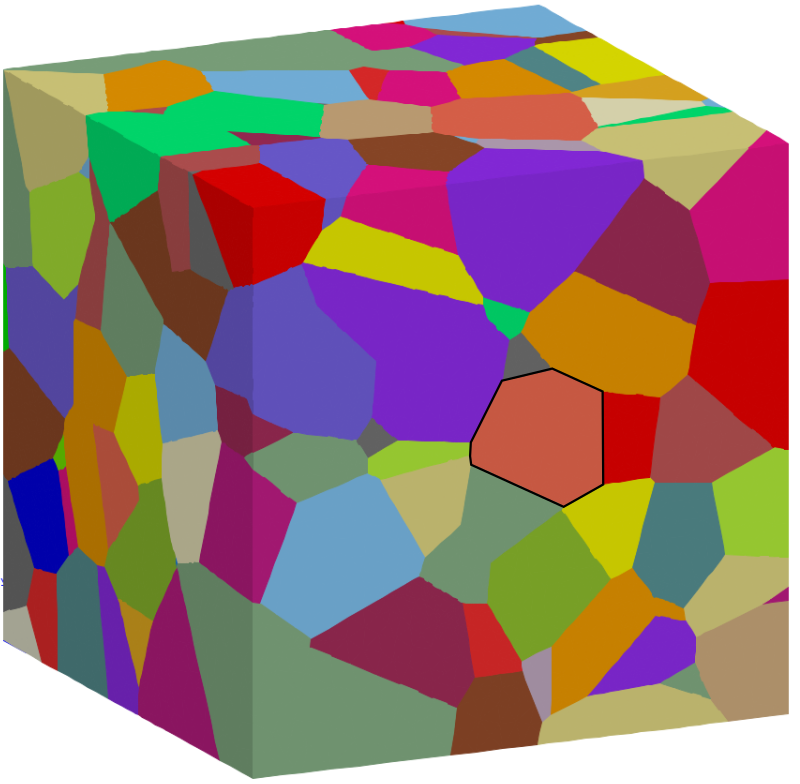

Reconstruct a three dimensional microstructure even using X-ray (diffraction) tomography presents a really challenging task because of the sub-micron size of binder pools and WC grains. Therefore, for our study of hardmetal mechanical behavior we developed an algorithm based on multiple truncation of Voronoi-grains by a randomly oriented planes. This algorithm enabling to construct microstructural CAD models for gmsh was implemented in voro++ library (I hope in near future render this implementation publically available in addition to generating hardmetal microstructures, this implementation allows to simply construct CAD models from voro++ tesselations), a trivial voxel-based implementation is also available.

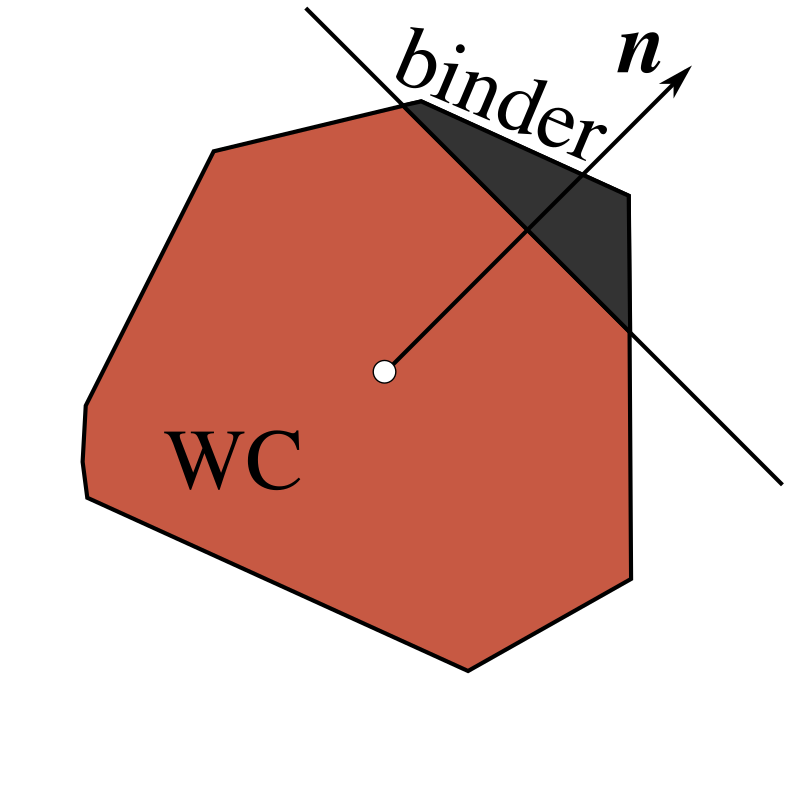

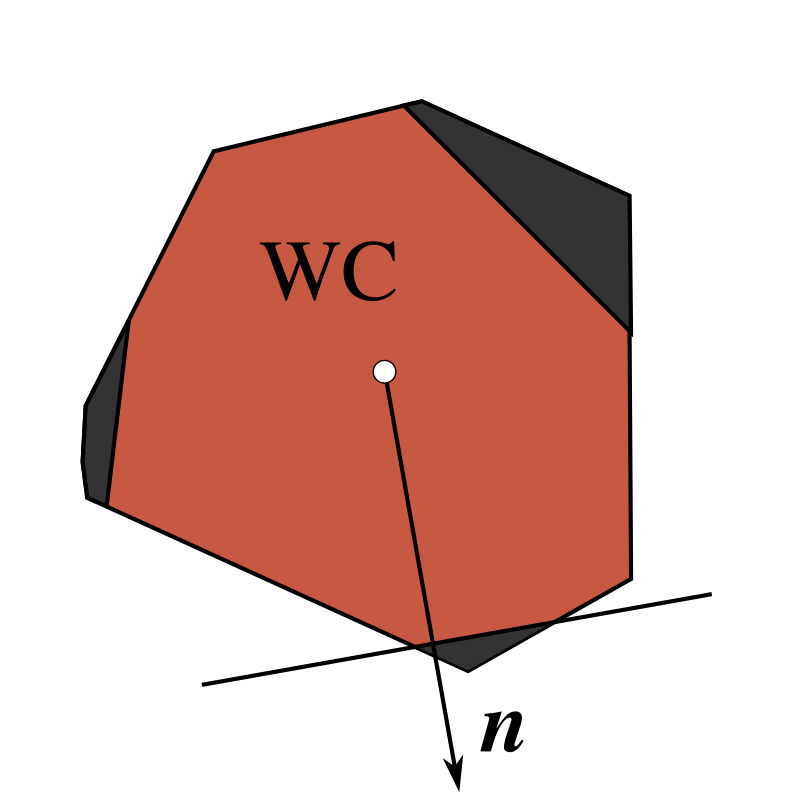

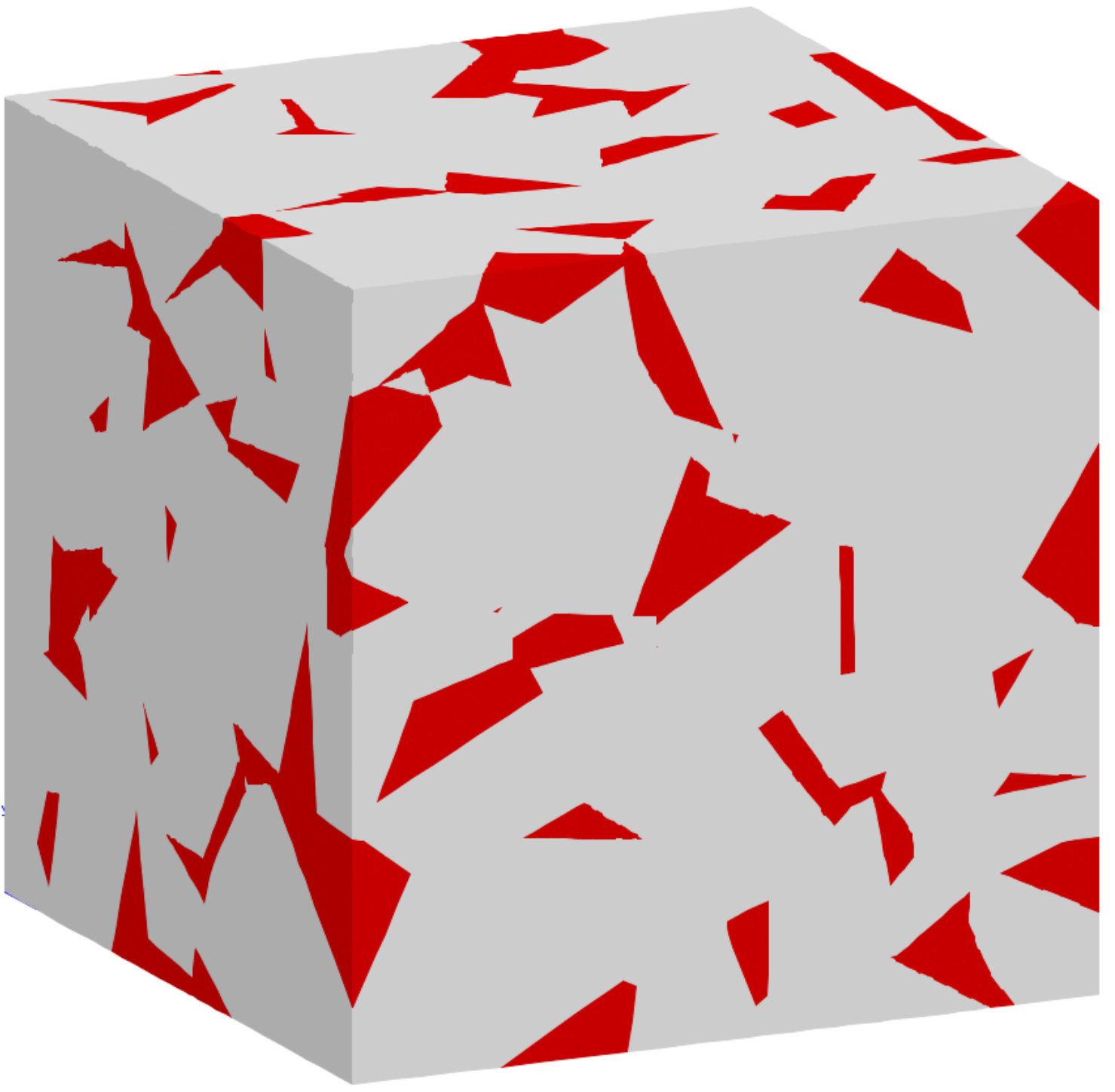

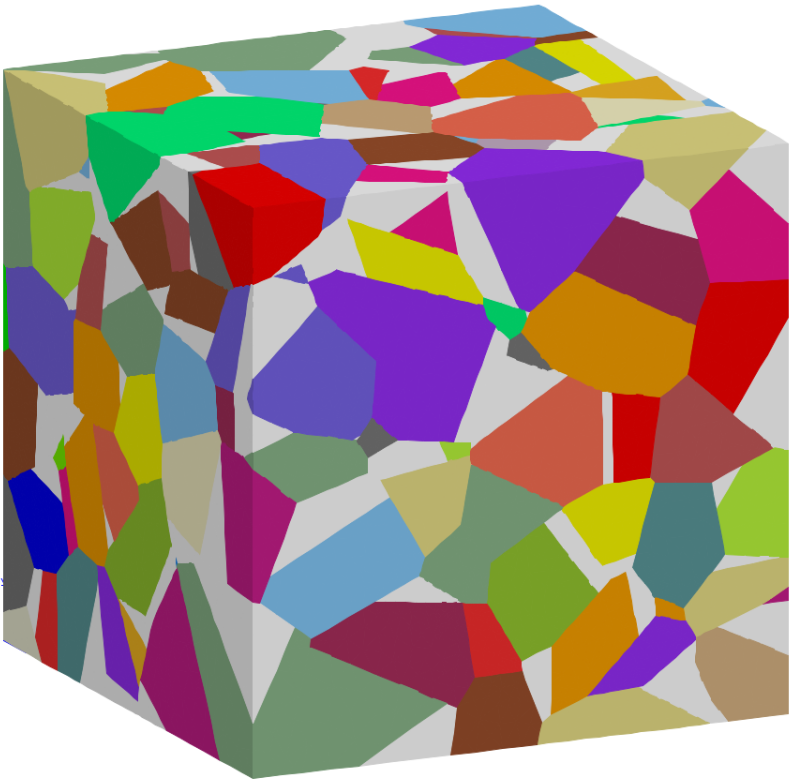

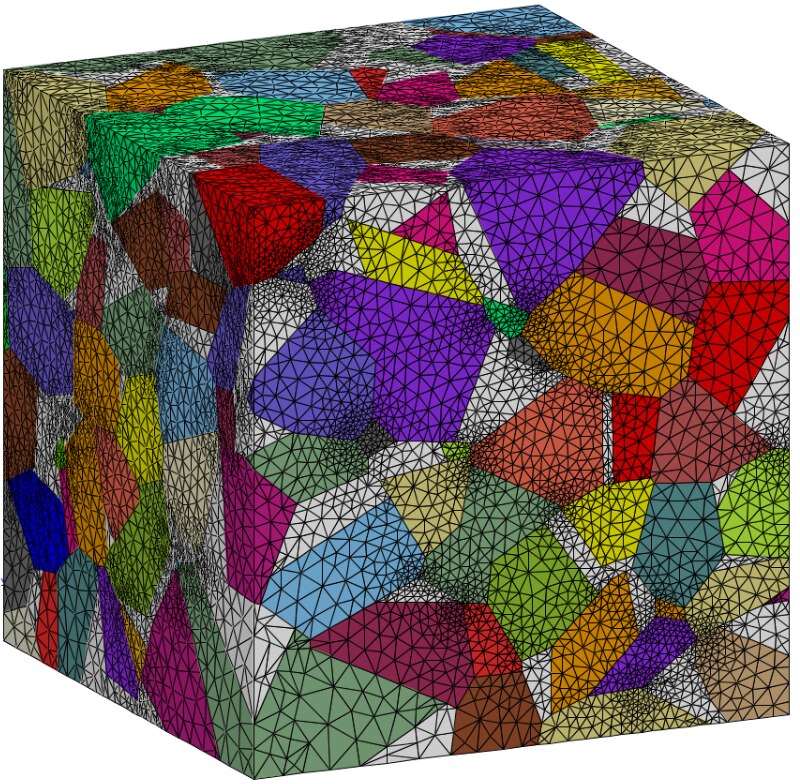

Demonstration of the truncated-Voronoi algorithm for reconstruction of cemented tungsten carbide microstructure: initial voronoi tesselation truncation of every grain (number of truncation and volume fraction are the used defined parameters) binder shown in red, WC grains in multicolor resulting finite element mesh.

Fig. Comparison of SEM image of WC/Co microstructure and generated microstructure for the same binder volume fraction.

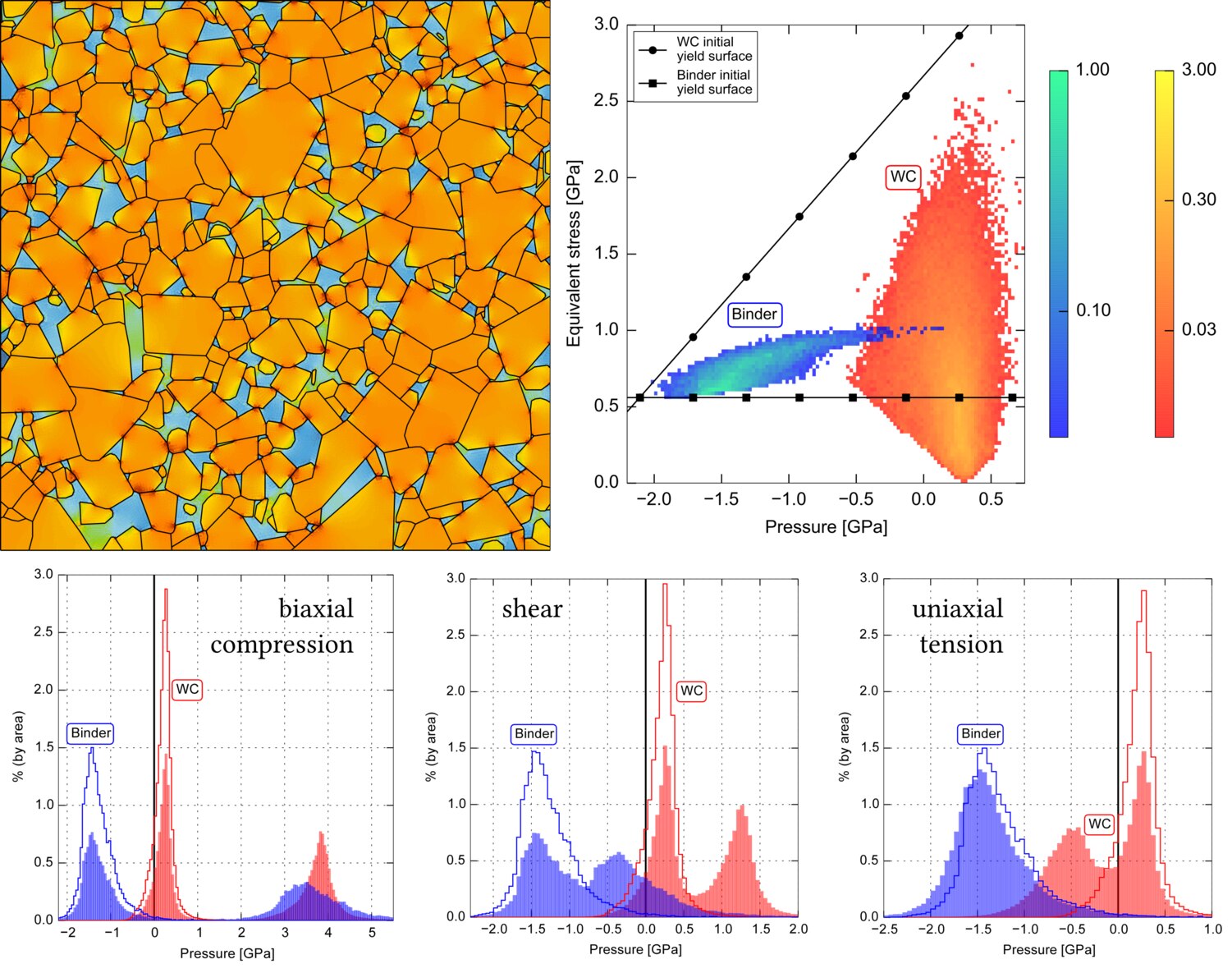

The obtained 2D and 3D microstructures were used to study mechanical behavior and statistics of stress-strain state in characteristic loading paths in drilling with and without taking into account residual cooling-induced stresses. The first interesting result is that the cooling-induced stress state under simple loading conditions (shear, tension, compression) results in two-maxima pressure distributions as shown in Fig. 23. Therefore, a mean-field model used with residual thermal stresses would report a meaningless results for the mean pressure located in between two maxima, thus missing completely the true contact state in the microstructure.

Fig. 23

Fig. 23

Contour plot of pressure distribution in WC/Co microstructure after thermal contraction from 800 °C to 20 °C emerging due to the different in thermal expansion coefficients of cobalt and WC, pressure- map after thermal contraction; lower panel – histograms of pressure distributions in binder and WC after biaxial compression, shear and uniaxial tension (initial histogram right after thermal contraction is shown by a solid line) demonstrating double-peak distribution for which the mean value is meaningless.

The second interesting result coming from this micromechanical study is that the mean-field model is incapable to deal correctly with strongly hydrostatic stress states. In Fig. 24 we compare initial yield surfaces obtained for mean-field and full-field models, demonstrating a pronounced cap for the latter and its absence for the former. In contact and impact, high hydrostatic pressures represent a very common stress state near the contact surface, so the mean-field models should be adjusted in order to capture correctly such regimes. Therefore, Georges Cailletaud suggested to convert the original -model into a hierarchical model or two-scale -model to capture properly the plastic onset under strongly hydrostatic deformation regimes. With Dmitry Tkalich we started to work on the implementation of this model, yet unfortunately this promising project was not finished.

Yield surface of WC/Co hardmetal for different binder contents (7.5%, 10%, 15%). Markers and colored master curves show the results of full-field finite element simulations (FE), black solid lines represent the results obtained by the mean-field (MF) -model. [76]

📚 References

- [79] D. Tkalich, G. Cailletaud, V.A. Yastrebov, A. Kane. “A micromechanical constitutive modeling of WC hardmetals using finite-element and uniform field models”. Mechanics of Materials, 105:166-187 (2017). [doi] [pdf]

- [76] D. Tkalich, V.A. Yastrebov, G. Cailletaud, A. Kane. “Multiscale Modeling of Cemented Tungsten Carbide in Hard Rock Drilling”. International Journal of Solids and Structures, 128:282-295 (2017). [doi] [pdf]

- Presentation “Multiscale wear modelling of cemented tungsten carbide tools in hard rock drilling” given at the conference “Computational Modeling of Complex Materials Across the Scales”, Nov 8, 2017. Paris, France [pdf]